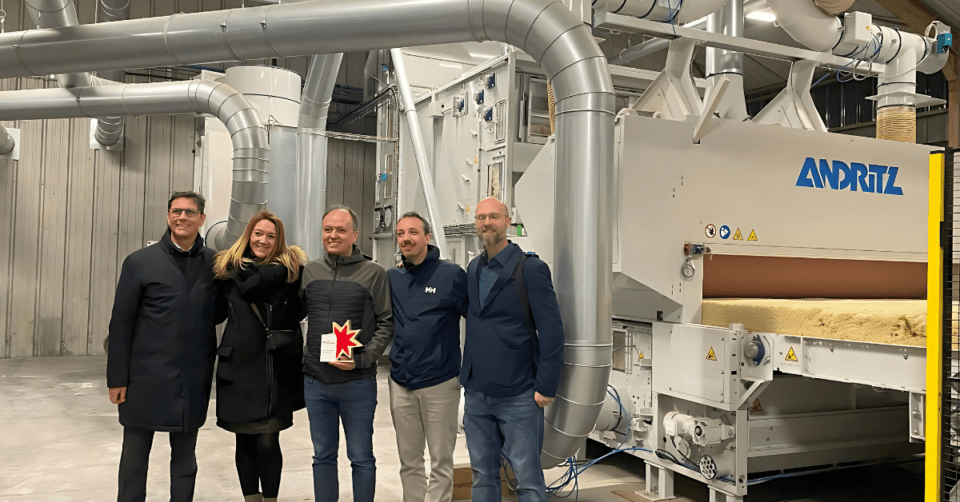

International technology group ANDRITZ has supplied and commissioned a neXline airlay system at the Carolina Nonwovens plant in Ohio.

This marks the first installation of the new generation airlay line in the United States. The state-of-the-art system processes recycled fibers into nonwoven for automotive and industrial sectors, helping to reduce waste and enhance resource efficiency.

Designed for ease of use and maintenance, ANDRITZ’s advanced equipment maximizes operational efficiency and reliability. With this new investment, Carolina Nonwoven strengthens its ability to produce high-quality nonwoven from industrial and post-consumer waste, in line with its commitment to sustainability and the circular economy. The company already operates an ANDRITZ airlay line at its plant in North Carolina.

“It was a pleasure to work with the ANDRITZ experts again. Thanks to their support, our team benefited from efficient training, enabling us to significantly enhance our capabilities,”says Ed Hull, COO of Carolina Nonwovens.

Carolina Nonwovens specializes in providing world-class nonwoven solutions using state-of-the-art airlay technology and superior raw materials. With deep expertise in fiber processing, the company offers a wide range of products for various markets such as acoustic and thermal insulation for the automotive, construction and appliance industries.

ANDRITZ GROUP

International technology group ANDRITZ provides advanced plants, equipment, services, and digital solutions for a wide range of industries, including pulp and paper, metals, hydropower, environmental, and others. Founded in 1852 and headquartered in Austria, the publicly listed group employs about 30,000 people at 280 locations in over 80 countries.

As a global leader in technology and innovation, ANDRITZ is committed to fostering progress that benefits customers, partners, employees, society, and the environment. The company’s growth is driven by sustainable solutions enabling the green transition, advanced digitalization for highest industrial performance, and comprehensive services that maximize the value of customers’ plants over their entire life cycle.